The use of FEP in UVC sterilisation equipment

In an increasingly regulated and safety-conscious world, the threat of contamination is ever growing. As a result, UVC sterilisation equipment is becoming more and more important for the medical and food and drink industries. Find out why FEP is the ideal material for UVC sterilisation and which fluoropolymer products are used in UVC sterilisation applications.

Which industries require UVC sterilisation

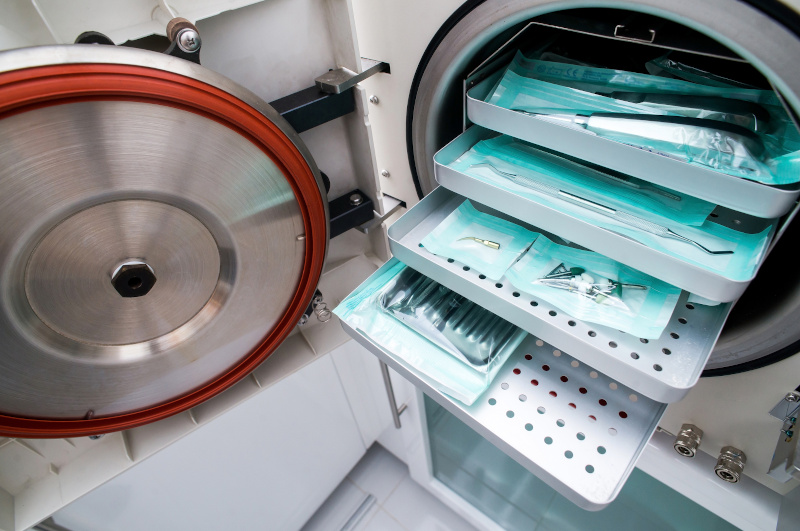

UVC is a strong ultraviolet light used to disinfect and destroy harmful microorganisms in liquids, the air and on surfaces. It is believed UVC is the most effective radiation to destroy bacteria and inactivate viruses. As a result, UVC radiation is used to sterilise food and drink applications, and medical equipment.

In the food and drink industry, this is a necessary practice as it eliminates pathogens and can extend the shelf life of products. UVC sterilisation is widely used to disinfect drinking water, sanitize wastewater and sterilise food contact surfaces.

In the medical sector, UV radiation is used to sterilise hospital equipment, diagnose a range of medical conditions and even treat cancer patients. With UVC technology, it is possible to destroy 99.9% of bacteria in seconds without the need for harmful chemicals.

Why FEP is the ideal fluoroplastic for UVC sterilisation

Given the high strength of ultraviolet rays, most polymers are not suited to UVC sterilisation. However, FEP is inert to ultraviolet rays and has a low absorption rate for UVC. With an FEP heat shrink sleeve, the UVC transmission rate of the lamps remains high at approximately 85%, thereby ensuring maximum performance.

FEP becomes only minimally degraded by the heat or UV rays emitted by the lamps. The fluoropolymer does not brittle or discolour when used with the strong light over time. The fluoroplastic coating also outlasts the life of the lamp. All in all, FEP is the ideal material to produce components for UVC sterilisation equipment.

FEP products used in UVC sterilisation applications

FEP products are used to deliver liquids either in front or around UVC lamps to sterilise their content, as well as to cover UVC lamps, making them shatterproof and ensuring compliance in glass free areas. The following products are most used in UVC sterilisation equipment:

Here at Adtech, we supply FEP tubing and FEP heat shrink sleeving in many standard sizes and in different wall thicknesses. We also produce special custom tubing to order. Using thermoforming technology, we can create retractable coils. Custom sizes can be made, and specialist fittings can be applied to meet the demands of your application.

We also manufacture heat shrinkable FEP to cover lamps and can cover all lamp configurations, including straight, compact, circline and tight U-bend styles. Used in schools and colleges, food processing plants and pharmaceutical plants, our shatterproof lamp coatings are IEC61549 compliant for use in glass free environments.

We are specialists in delivering innovative fluoropolymer solutions for your technical applications. Find out more about Fluoroplastics in the Sterilisation Industry.

Share this article:

Related News Articles