Case study: Custom FEP probe cover

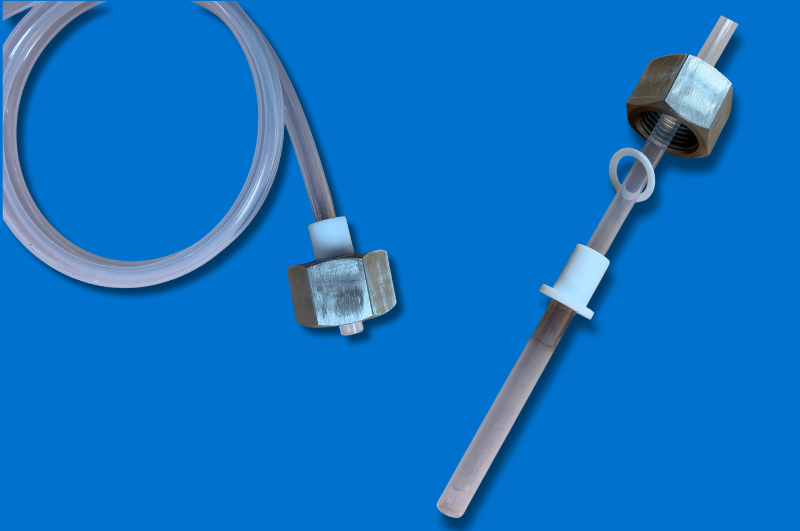

We were approached by a customer who was looking to improve their existing level detection probe, used in automotive and marine applications. The discussions led to the development and subsequent production of a bespoke FEP probe cover for their sensor probes.

The project criteria: Bespoke FEP probe cover

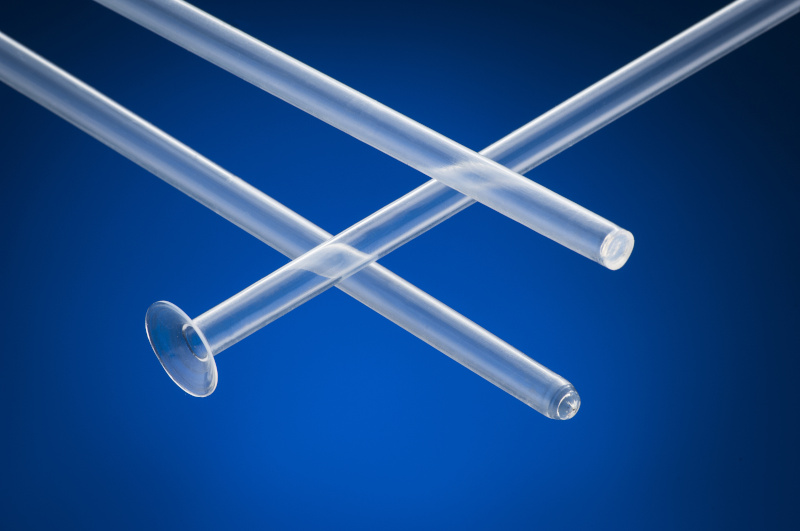

The criteria was that the coating had to be inert, as thin as possible along the length of the probe, with particular attention paid to the thickness of the sealed tip, to aid response times. In addition to this, the internal length of the cover was critical, and a flange was required on the open end, so that this could be used as a sealing face for when the probe was in situ.

Our client also wanted to offer their customers greater flexibility, so that the sensor could be supplied at any variable length between 100mm and 2000mm.

The solution: Bespoke fabrication process

The need for this flexibility meant that our development team had to devise a long-term production method that could meet the customer’s demands and have short set up times, so that we could optimise production capacity and offer a wide range of variable lengths all in one production batch.

Being involved at the development stages of the product meant Adtech could give advice on how the client’s needs could be met, suitable fluoroplastic materials and fabrication processes.

This then enabled our development team to use their expertise in these areas, to quickly supply proto-types for testing and build bespoke tooling that not only could meet the demands of the need for variable lengths, but that could also be easily modified in the future, as production ramped up to meet the forecasted sales.

Here at Adtech, we are specialists in delivering innovative fluoropolymer solutions for your technical applications. We understand that every customer’s application is different, so our knowledgeable customer service and R&D teams are on hand to discuss your project and application.

Get in touch today to ask for advice or to discuss your requirements:

t: +44 (0)1285 762000

e: sales@adtech.co.uk

Share this article:

Related News Articles